Page 93 - Catalogo de Boquillas - Industrysystem

P. 93

Dimensions are approximate. Check with BETE for critical dimension applications.

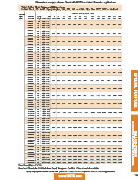

Twist & Dry Flow Rates and Dimensions

Hollow Cone, 50° to 80° Spray Angles, 1/4 , 3/8 , 1/2 and 3/4 Pipe Size NPT, BSP or Welded

LITERS PER HOUR @ BAR

Female

Pipe Nozzle Spray Dia K 15 35 50 70 90 100 120 150 175 200 275 350

Size Number Angle Swirl (mm) Factor bar bar bar bar bar bar bar bar bar bar bar bar

TD6-46 55° SW6 1.17

TD5-52 65° SW5 1.32

27.4 106 162 193 229 259 273 300 335 362 387 453 512

TD4-61 75° SW4 1.55

TD3-70 80° SW3 1.78

TD6-52 55° SW6 1.32

TD5-58 65° SW5 1.47 31.9 124 189 226 267 303 319 349 391 422 451 529 597

TD4-70 75° SW4 1.78

TD7-49 50° SW7 1.24

TD6-55 60° SW6 1.40

36.5 141 216 258 305 346 365 399 447 482 516 605 682

TD5-64 70° SW5 1.63

TD4-76 80° SW4 1.93

TD7-52 50° SW7 1.32

TD6-61 60° SW6 1.55 41.0 159 243 290 343 389 410 449 502 543 580 680 767

TD5-70 70° SW5 1.78

TD7-58 55° SW7 1.47

TD6-64 65° SW6 1.63

45.6 177 270 322 381 432 456 499 558 603 645 756 853

TD5-76 75° SW5 1.93

TD4-91 80° SW4 2.31

TD7-61 55° SW7 1.55

TD6-70 65° SW6 1.78 50.1 194 297 355 419 476 501 549 614 663 709 831 938

TD5-82 75° SW5 2.08

TD7-64 55° SW7 1.63

TD6-76 65° SW6 1.93 54.7 212 324 387 458 519 547 599 670 724 773 907 1020

TD5-88 75° SW5 2.24

TD8-67 50° SW8 1.70

TD7-76 60° SW7 1.93

68.4 265 404 483 572 649 684 749 837 904 967 1130 1280

TD6-88 70° SW6 2.24

TD5-109 80° SW5 2.77

TD8-76 50° SW8 1.93

TD7-85 65° SW7 2.16 82.0 318 485 580 686 778 820 899 1010 1090 1160 1360 1540

TD6-103 75° SW6 2.62 SPECIAL PURPOSE

TD8-82 55° SW8 2.08

TD7-97 65° SW7 2.46 95.7 371 566 677 801 908 957 1050 1170 1270 1350 1590 1790

TD6-115 75° SW6 2.92

TD9-82 50° SW9 2.08

TD8-91 60° SW8 2.31

109 424 647 773 915 1040 1090 1200 1340 1450 1550 1810 2050

TD7-106 70° SW7 2.69

TD6-127 80° SW6 3.23

TD9-88 50° SW9 2.24

TD8-100 60° SW8 2.54

123 477 728 870 1030 1170 1230 1350 1510 1630 1740 2040 2300

TD7-118 70° SW7 3.00

TD6-142 80° SW6 3.61

TD9-94 55° SW9 2.39

TD8-106 65° SW8 2.69 137 530 809 967 1140 1300 1370 1500 1680 1810 1930 2270 2560

TD7-127 75° SW7 3.23

TD9-106 55° SW9 2.69

TD8-121 65° SW8 3.07 160 618 944 1130 1340 1510 1600 1750 1950 2110 2260 2650 2980

TD7-145 75° SW7 3.68

TD10-103 50° SW10 2.62

TD9-115 60° SW9 2.92 182 706 1080 1290 1530 1730 1820 2000 2230 2410 2580 3020 3410

TD8-133 70° SW8 3.38

TD10-118 55° SW10 3.00

TD9-127 60° SW9 3.23 205 794 1210 1450 1720 1950 2050 2250 2510 2710 2900 3400 3840

TD8-145 70° SW8 3.68 Call for the name of your nearest BETE representative. CALL 413-772-0846

TD9-136 65° SW9 3.45

228 883 1350 1610 1910 2160 2280 2500 2790 3020 3220 3780 4260

TD8-157 75° SW8 3.99

TD9-148 65° SW9 3.76 251 971 1480 1770 2100 2380 2510 2750 3070 3320 3550 4160 4690

TD10-136 60° SW10 3.45

274 1060 1620 1930 2290 2590 2740 3000 3350 3620 3870 4540 5120

TD9-154 70° SW9 3.91

TD10-151 60° SW10 3.84 296 1150 1750 2100 2480 2810 2960 3250 3630 3920 4190 4910 5540

TD10-157 65° SW10 3.99 319 1240 1890 2260 2670 3030 3190 3500 3910 4220 4510 5290 5970

Flow Rate (l/hr) = K bar

Standard Materials: 316 Stainless Steel, Tungsten Carbide. Other materials available.

Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

www.BETE.com 111

Twist & Dry Flow Rates and Dimensions

Hollow Cone, 50° to 80° Spray Angles, 1/4 , 3/8 , 1/2 and 3/4 Pipe Size NPT, BSP or Welded

LITERS PER HOUR @ BAR

Female

Pipe Nozzle Spray Dia K 15 35 50 70 90 100 120 150 175 200 275 350

Size Number Angle Swirl (mm) Factor bar bar bar bar bar bar bar bar bar bar bar bar

TD6-46 55° SW6 1.17

TD5-52 65° SW5 1.32

27.4 106 162 193 229 259 273 300 335 362 387 453 512

TD4-61 75° SW4 1.55

TD3-70 80° SW3 1.78

TD6-52 55° SW6 1.32

TD5-58 65° SW5 1.47 31.9 124 189 226 267 303 319 349 391 422 451 529 597

TD4-70 75° SW4 1.78

TD7-49 50° SW7 1.24

TD6-55 60° SW6 1.40

36.5 141 216 258 305 346 365 399 447 482 516 605 682

TD5-64 70° SW5 1.63

TD4-76 80° SW4 1.93

TD7-52 50° SW7 1.32

TD6-61 60° SW6 1.55 41.0 159 243 290 343 389 410 449 502 543 580 680 767

TD5-70 70° SW5 1.78

TD7-58 55° SW7 1.47

TD6-64 65° SW6 1.63

45.6 177 270 322 381 432 456 499 558 603 645 756 853

TD5-76 75° SW5 1.93

TD4-91 80° SW4 2.31

TD7-61 55° SW7 1.55

TD6-70 65° SW6 1.78 50.1 194 297 355 419 476 501 549 614 663 709 831 938

TD5-82 75° SW5 2.08

TD7-64 55° SW7 1.63

TD6-76 65° SW6 1.93 54.7 212 324 387 458 519 547 599 670 724 773 907 1020

TD5-88 75° SW5 2.24

TD8-67 50° SW8 1.70

TD7-76 60° SW7 1.93

68.4 265 404 483 572 649 684 749 837 904 967 1130 1280

TD6-88 70° SW6 2.24

TD5-109 80° SW5 2.77

TD8-76 50° SW8 1.93

TD7-85 65° SW7 2.16 82.0 318 485 580 686 778 820 899 1010 1090 1160 1360 1540

TD6-103 75° SW6 2.62 SPECIAL PURPOSE

TD8-82 55° SW8 2.08

TD7-97 65° SW7 2.46 95.7 371 566 677 801 908 957 1050 1170 1270 1350 1590 1790

TD6-115 75° SW6 2.92

TD9-82 50° SW9 2.08

TD8-91 60° SW8 2.31

109 424 647 773 915 1040 1090 1200 1340 1450 1550 1810 2050

TD7-106 70° SW7 2.69

TD6-127 80° SW6 3.23

TD9-88 50° SW9 2.24

TD8-100 60° SW8 2.54

123 477 728 870 1030 1170 1230 1350 1510 1630 1740 2040 2300

TD7-118 70° SW7 3.00

TD6-142 80° SW6 3.61

TD9-94 55° SW9 2.39

TD8-106 65° SW8 2.69 137 530 809 967 1140 1300 1370 1500 1680 1810 1930 2270 2560

TD7-127 75° SW7 3.23

TD9-106 55° SW9 2.69

TD8-121 65° SW8 3.07 160 618 944 1130 1340 1510 1600 1750 1950 2110 2260 2650 2980

TD7-145 75° SW7 3.68

TD10-103 50° SW10 2.62

TD9-115 60° SW9 2.92 182 706 1080 1290 1530 1730 1820 2000 2230 2410 2580 3020 3410

TD8-133 70° SW8 3.38

TD10-118 55° SW10 3.00

TD9-127 60° SW9 3.23 205 794 1210 1450 1720 1950 2050 2250 2510 2710 2900 3400 3840

TD8-145 70° SW8 3.68 Call for the name of your nearest BETE representative. CALL 413-772-0846

TD9-136 65° SW9 3.45

228 883 1350 1610 1910 2160 2280 2500 2790 3020 3220 3780 4260

TD8-157 75° SW8 3.99

TD9-148 65° SW9 3.76 251 971 1480 1770 2100 2380 2510 2750 3070 3320 3550 4160 4690

TD10-136 60° SW10 3.45

274 1060 1620 1930 2290 2590 2740 3000 3350 3620 3870 4540 5120

TD9-154 70° SW9 3.91

TD10-151 60° SW10 3.84 296 1150 1750 2100 2480 2810 2960 3250 3630 3920 4190 4910 5540

TD10-157 65° SW10 3.99 319 1240 1890 2260 2670 3030 3190 3500 3910 4220 4510 5290 5970

Flow Rate (l/hr) = K bar

Standard Materials: 316 Stainless Steel, Tungsten Carbide. Other materials available.

Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

www.BETE.com 111